When you’re delivering a live refurbishment, an occupied fit-out, or any project with dense MEP and tight access, the biggest risk is rarely what’s on the drawings — it’s what’s actually on site.

That’s why 3D laser scanning (often called reality capture) is quickly moving from “nice to have” to standard practice. It gives teams an accurate digital snapshot of existing conditions so design decisions, coordination, procurement and planning are based on facts — not assumptions.

What is 3D laser scanning (and what do you get from it)?

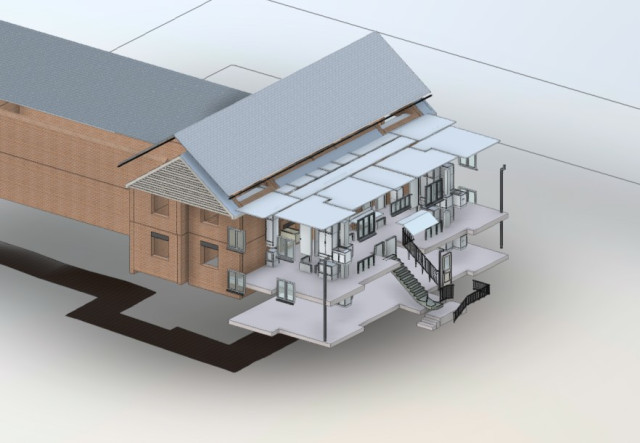

A 3D laser scan captures millions of measurement points to create a point cloud — a highly detailed 3D representation of the space. From that dataset, project teams can generate outputs such as:

- Verified existing-condition drawings (2D CAD plans/sections/elevations)

- Scan-to-BIM models (commonly Revit) for coordination and design development

- MEP and structural coordination models for clash detection and installation planning

- A clear digital record that supports handover, future maintenance, and later alterations

In simple terms: you replace “best guess” surveys with site truth.

Why it’s becoming essential (not optional)

Construction programmes are compressing, buildings are getting more complex, and refurbishment pipelines are growing. At the same time, teams are under pressure to reduce abortive work, minimise disruption in occupied environments, and improve certainty.

3D scanning supports all of that by improving the quality of information at the point it matters most: before decisions get locked in.

Industry research consistently links poor information and miscommunication with avoidable rework, and rework is widely recognised as a material cost and programme risk on projects.

The practical benefits we see on real projects

1) Fewer surprises once ceilings come down

Traditional measured surveys can miss critical constraints — especially above ceilings, in risers, plant rooms, congested corridors and legacy refurb areas. A point cloud provides a reliable basis for identifying constraints early, reducing late-stage redesign and site-based firefighting.

2) Faster, better MEP coordination and clash avoidance

In MEP-heavy environments, coordination is often where projects win or lose time. Scan-to-BIM models and point clouds enable more accurate clash detection and buildable solutions — before you’re dealing with stoppages on site.

3) Better cost and programme certainty

With clearer existing-condition information, teams can produce better tender information, reduce assumptions in pricing, and minimise change driven by unknowns. That typically means fewer variations and a calmer delivery phase.

4) Remote decision-making (without repeated site visits)

Design teams can interrogate scan data off-site, measure elements directly, and resolve queries quickly — especially useful when access is limited, the building is occupied, or the project team is spread across locations.

5) A stronger project record from day one

A scan creates a defensible baseline that supports:

- progress tracking and change control

- dispute avoidance (clear evidence of existing conditions)

- future maintenance planning and “as-built” documentation expectations

Where 3D scanning adds the most value

3D scanning can support almost any project, but it delivers the biggest return when any of the following are true:

- Refurbishment / retrofit with incomplete or unreliable record drawings

- Complex MEP, heavy services coordination, tight risers and restricted zones

- Occupied buildings, where disruption and repeat access must be minimised

- Time-critical programmes, where early certainty prevents later delay

- Specialist environments like labs, healthcare, education, plant rooms, and mission-critical areas

- Heritage or complex geometry, where manual measurement becomes slow and risky

In these scenarios, a scan often pays for itself by preventing a small number of high-impact issues.

How to build 3D scanning into your project (a simple workflow)

To get real value, scanning should be treated as a project input — not just a technical add-on. A typical approach looks like this:

Step 1: Define the purpose (and the outputs) early

Start with the decisions you need to make:

- is this for feasibility and option development?

- design coordination and clash management?

- procurement and contractor tendering?

- validation before installation?

- record / handover?

Then specify deliverables accordingly: point cloud only, CAD drawings, Scan-to-BIM model, tolerance requirements, coverage areas, and file formats.

Step 2: Capture at the right time

Common scanning points include:

- early feasibility / survey stage

- post-strip-out (often the moment of greatest truth)

- pre-installation validation in critical areas

- final as-built capture (when required by the client or FM team)

Step 3: Make sure the data is actually used

The difference between “we scanned it” and “we benefited from it” is governance:

- the scan becomes the single source of truth for coordination

- RFIs and design queries reference the model/point cloud

- design freezes are based on verified conditions

- contractors are briefed clearly on what the scan is (and isn’t)

Common pitfalls (and how to avoid them)

- Unclear scope: scanning the wrong areas or missing key risers/voids

- Wrong level of detail: data too heavy to use, or too light to trust

- No tolerance alignment: outputs not suitable for coordination decisions

- Data sitting in a folder: not integrated into the design and delivery process

- Late commissioning: scanning after key decisions have already been made

The fix is simple: treat scanning as part of your information management and risk strategy, with clear outputs and owners.

How Rockall Projects helps

At Rockall Projects, we support clients in using 3D scanning and reality capture in a way that improves outcomes — not just producing data for the sake of it.

We typically help by:

- advising when scanning will deliver the best return (and when it won’t)

- defining the right deliverables: point clouds, CAD outputs, Scan-to-BIM models

- coordinating the scanning programme with access constraints and phasing

- integrating the outputs into design development, coordination and change control

- strengthening tender information to reduce contractor assumptions and risk pricing

- keeping design, cost and programme aligned as decisions are made

In short: we help you turn “existing conditions” from a risk into a managed input.

FAQs

Is 3D laser scanning accurate enough for refurbishment design?

Yes — when the scan is captured and processed correctly, it provides a high-confidence basis for design coordination and dimensional verification, particularly in complex MEP environments.

What’s the difference between a measured survey and a point cloud survey?

A measured survey typically provides selective dimensions and drawings. A point cloud is a dense 3D dataset that can be measured and modelled across the scanned area, giving broader visibility of constraints.

Do I always need a Scan-to-BIM model?

Not always. Some projects only need the point cloud; others benefit from a model for coordination and clash detection. The right answer depends on your risks, complexity and decision points.

When is the best time to scan an existing building?

Early, and again after strip-out in key areas where hidden conditions are likely to affect coordination and programme.