What we do

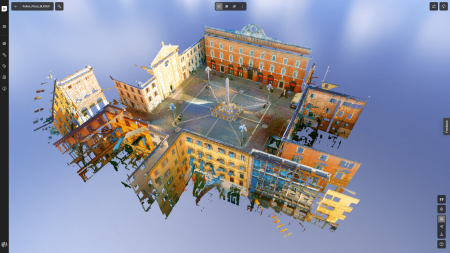

Rockall Projects provides building 3D laser scanning to capture accurate existing conditions for design, refurbishment, fit-out and verification. The output is a registered point cloud that your team can rely on as a baseline for coordination and decision-making—particularly where record drawings are incomplete, outdated, or missing.

We deliver scan data in the formats design teams and contractors actually use, with a clear scope, sensible segmentation, and documentation of any access/visibility constraints.

Typical uses for building laser scanning

3D laser scanning is most valuable when uncertainty creates programme and cost risk:

- Refurbishment and fit-out projects needing reliable as-built geometry

- Design coordination for complex interfaces (structure/MEP/architecture)

- Verification of installed works or critical dimensions

- Congested or complex zones: plant rooms, risers, ceiling voids, service corridors

- Clash avoidance before construction and during sequencing

- Change control and reducing RFIs caused by inaccurate base information

Deliverables

We agree deliverables at enquiry stage so you receive exactly what your workflow needs.

Common deliverables include:

- Registered point cloud in agreed formats (e.g., E57, RCP/RCS, LAS/PTS if required)

- Structured datasets by level / zone / area for easy navigation

- Basic scan plan / coverage notes (what was captured and any limitations)

Where required: targeted outputs such as 2D plans/sections derived from the point cloud, or inputs prepared for modelling (Scan to BIM / CAD)

If your team uses a CDE or specific naming conventions, we can align packaging and naming to suit.

Accuracy and what affects it

Laser scanning can achieve high accuracy, but outcomes depend on how the survey is planned and executed. Key factors include:

- line of sight and access (occlusions are the biggest constraint)

- reflective/glazed surfaces and tight congested areas

- scale and complexity of the environment

- control strategy (where required) and registration approach

- required tolerance and intended use (coordination vs verification vs fabrication interface)

We define the fit-for-purpose accuracy at the start so expectations are clear and deliverables match the project need.

Our process

A straightforward, professional workflow:

- Scope and planning

Areas, access, working hours, constraints, required outputs and formats. - Site capture

Efficient scanning plan to achieve coverage with minimal disruption. - Registration and data preparation

Point cloud alignment, cleaning where appropriate, and segmentation for usability. - QA and checks

Registration checks, review of coverage, and documentation of any limitations. - Delivery and handover

File set packaged in agreed formats with simple guidance on how it’s structured.

Example use cases

Replace these with named projects as you build case studies:

- Refurb base data for design development

Reliable existing-condition geometry to reduce rework and uncertainty. - Coordination of congested zones

Capturing plant rooms, risers and corridors to support clash avoidance. - Verification and change control

Confirming key dimensions and interfaces before committing to construction.

Related Services

Reach out to see how we can assist you

For expert advice and consultancy on your project, contact us today.